Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Permanent magnet slurry magnetic separator series

Permanent magnet slurry magnetic separator series

Dry electromagnetic separator automatic type

Dry electromagnetic separator automatic type

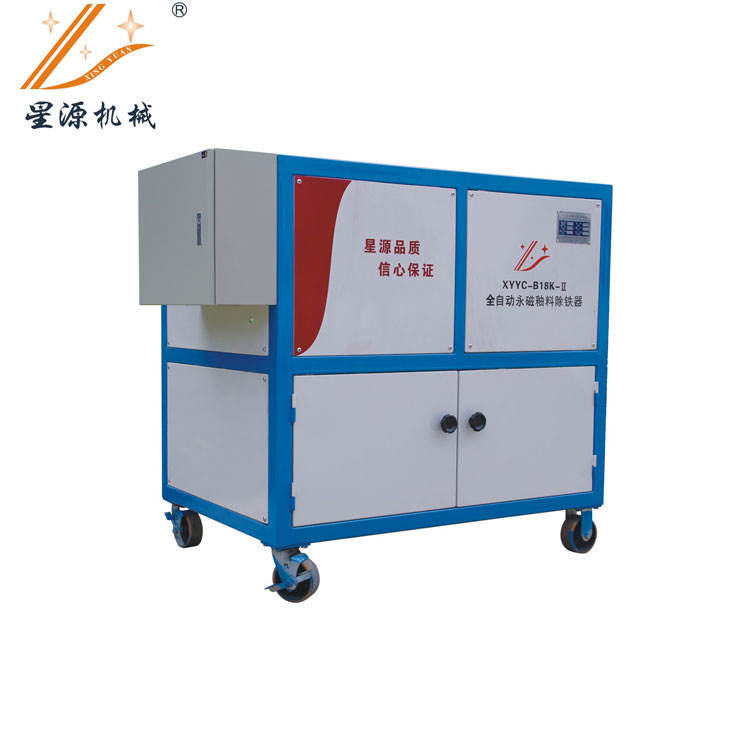

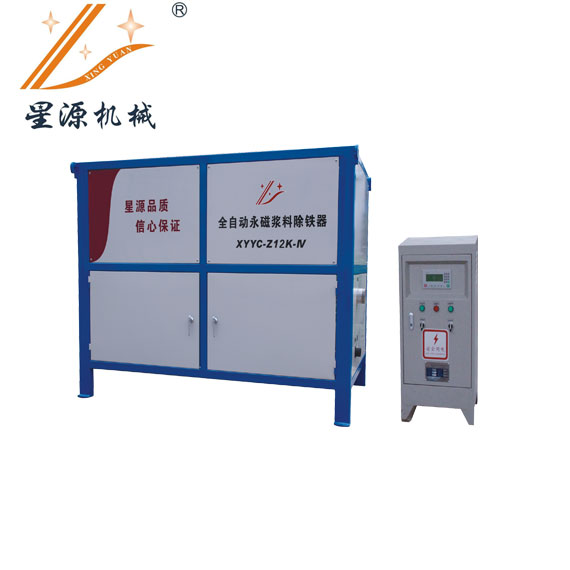

Automatic permanent magnet iron remover series

Automatic permanent magnet iron remover series

Magnetic products

Magnetic products

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

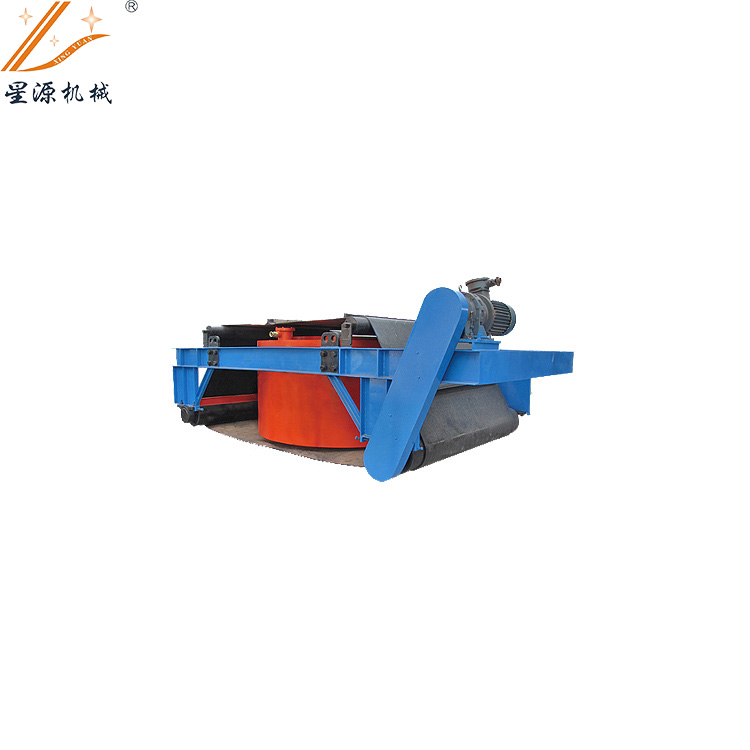

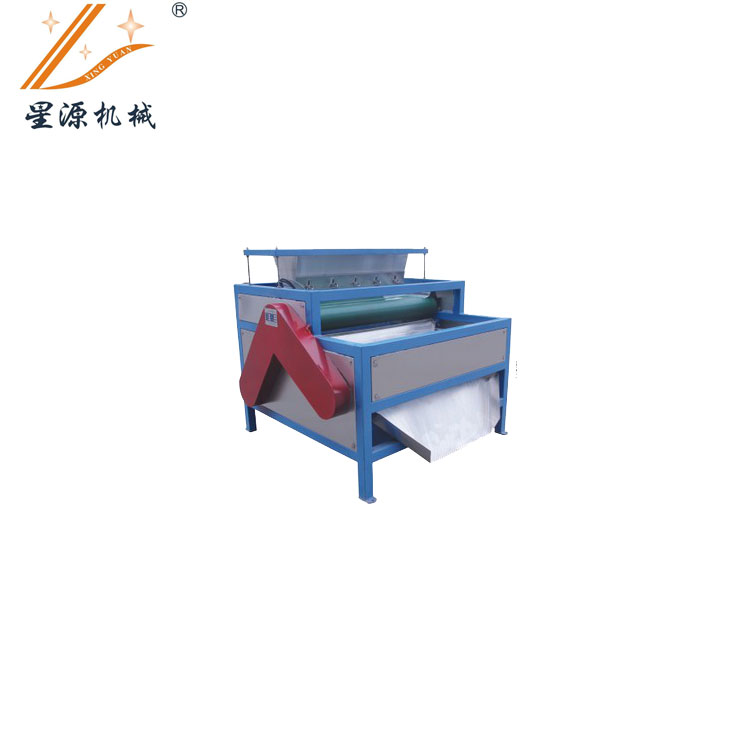

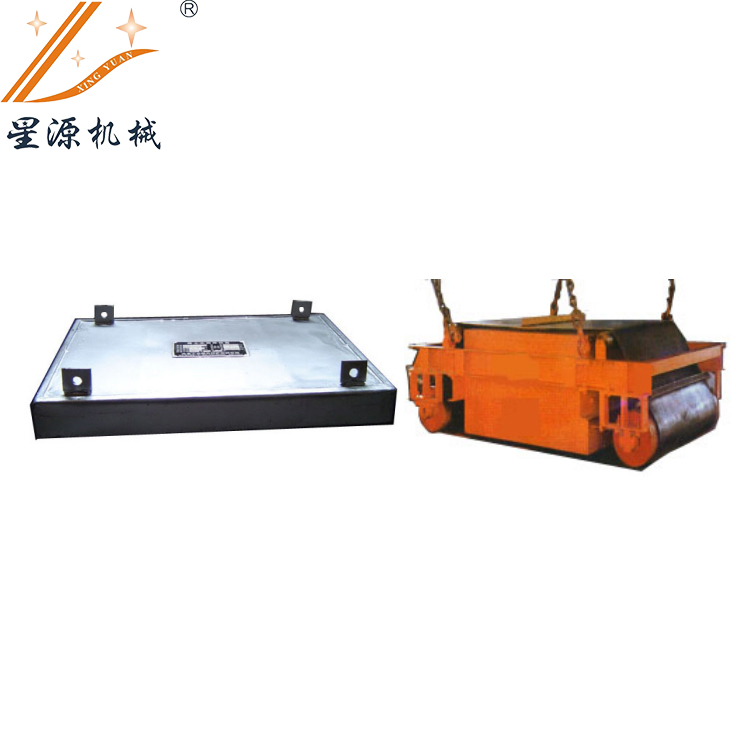

Permanent magnet belt iron remover

Permanent magnet belt iron remover

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

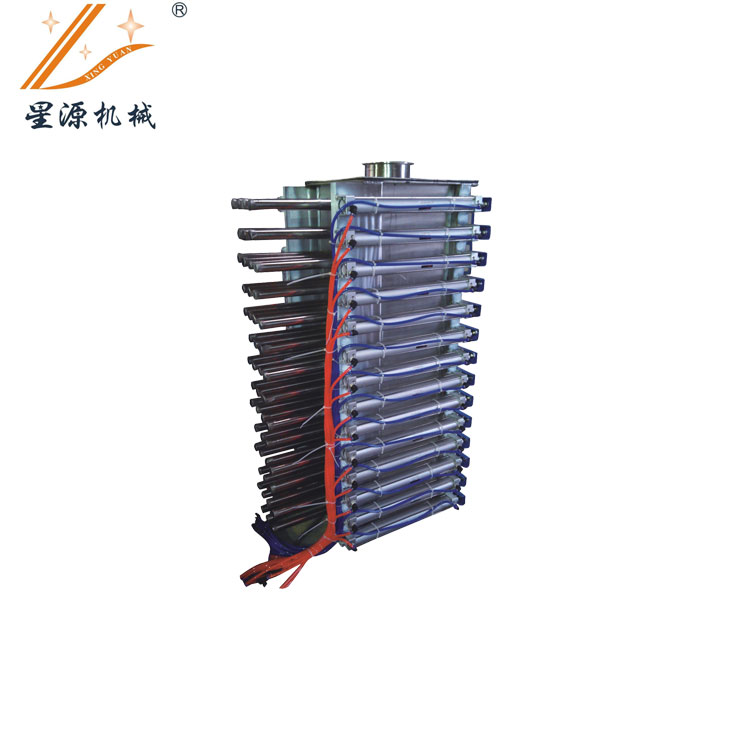

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

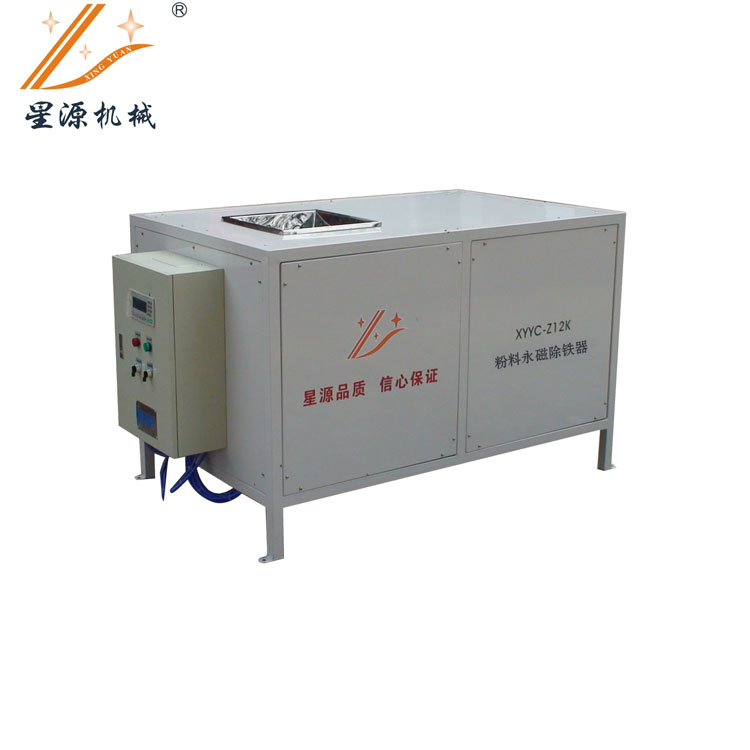

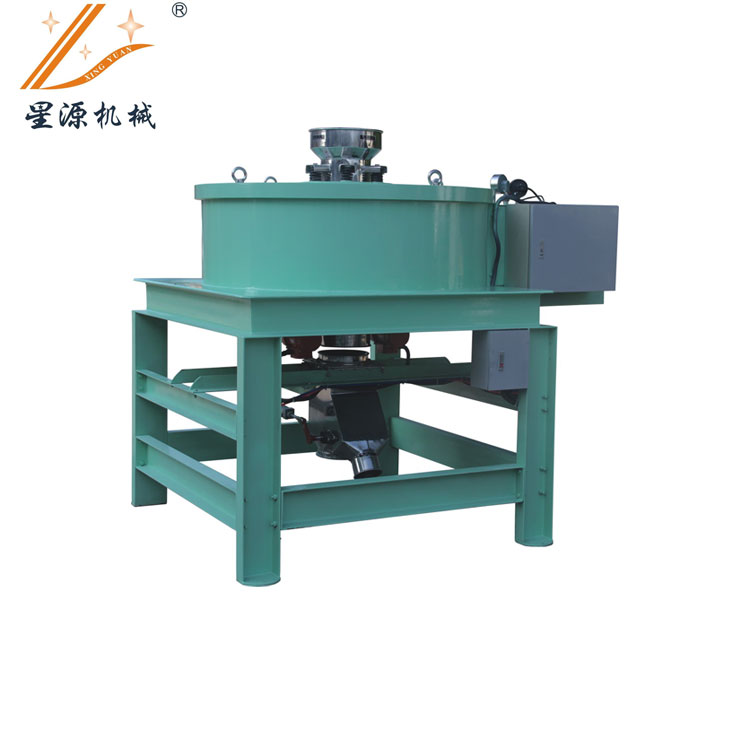

Automatic powder permanent magnet iron remover series

Automatic powder permanent magnet iron remover series

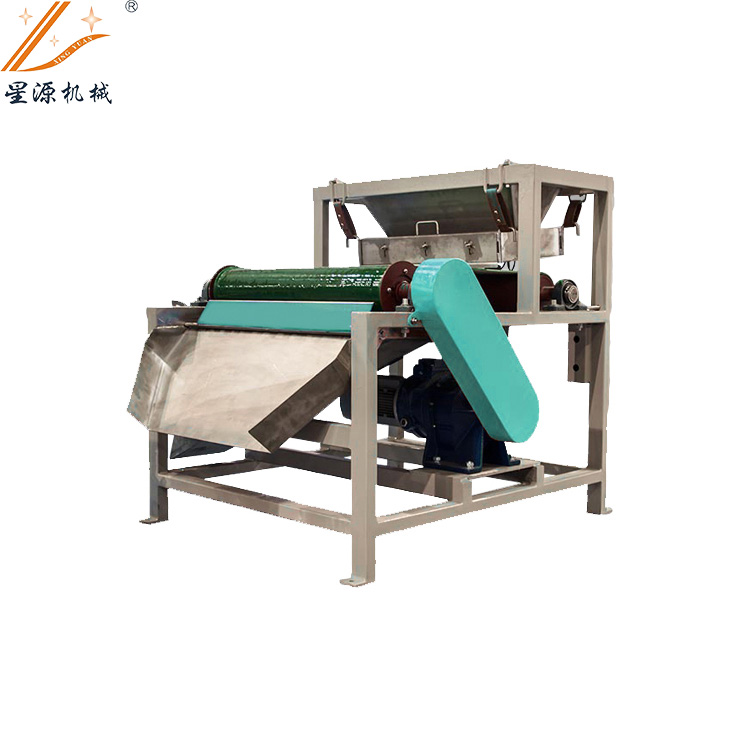

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

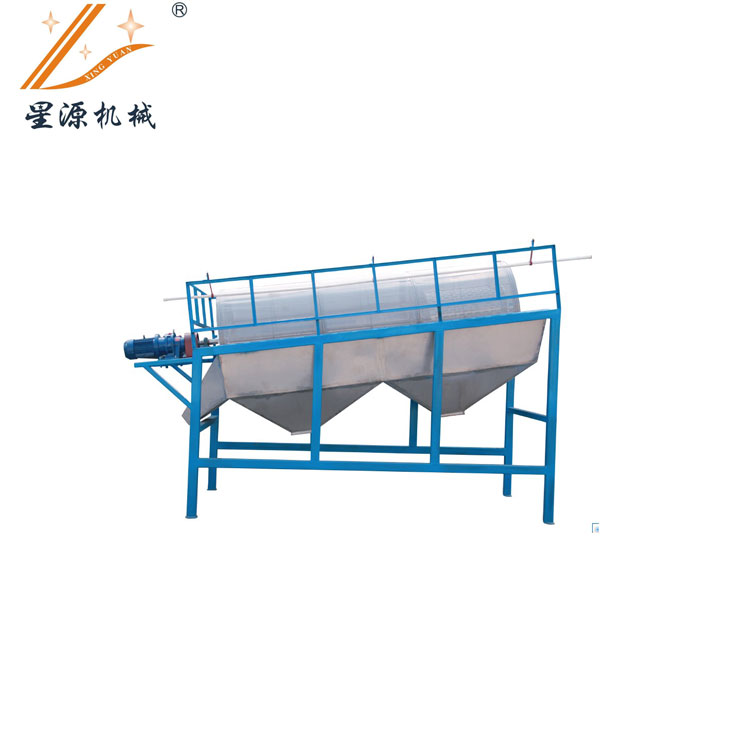

Automatic slurry permanent magnet iron remover series

Automatic slurry permanent magnet iron remover series

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

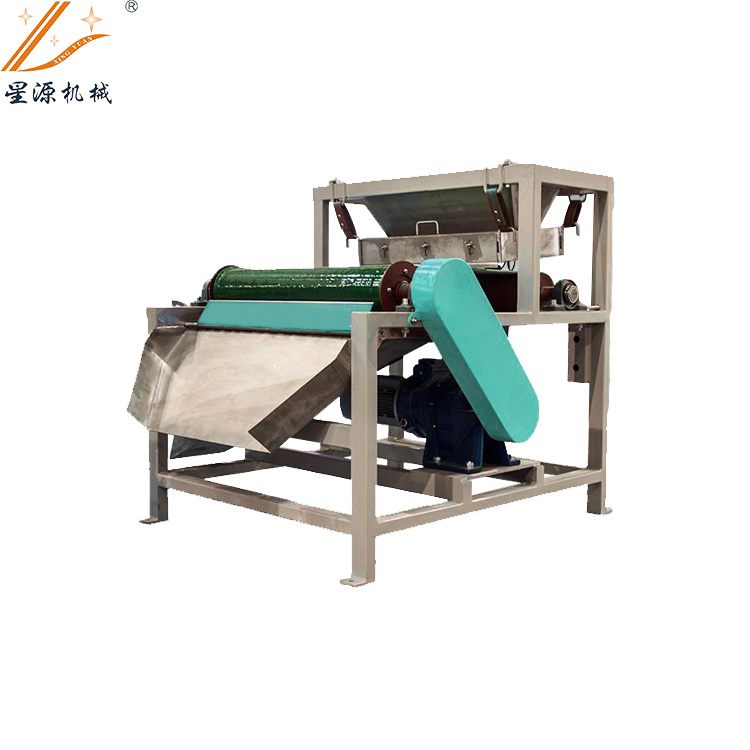

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Drawer type permanent magnet eliminator series

Drawer type permanent magnet eliminator series

Vertical ring high gradient magnetic separator series

Vertical ring high gradient magnetic separator series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

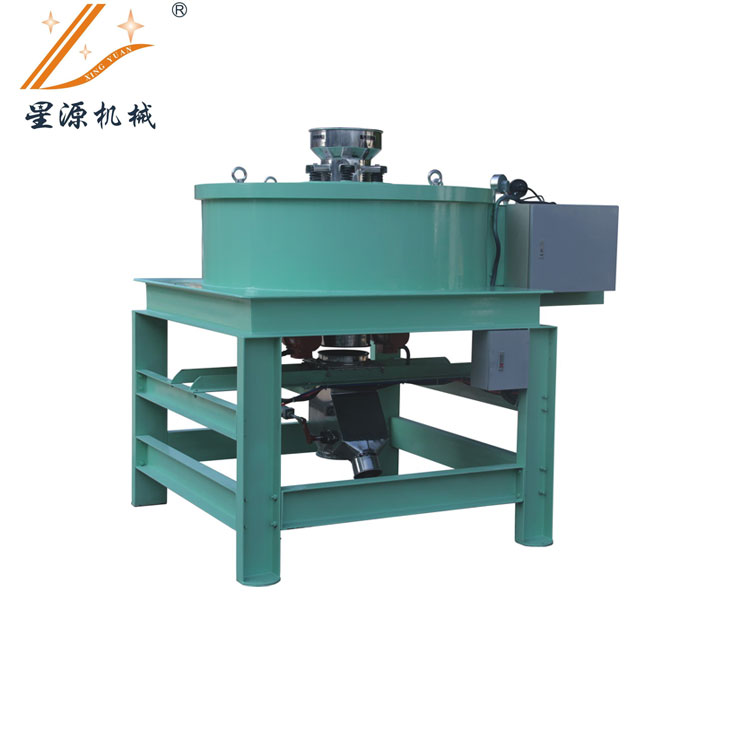

Permanent magnet rotating dry powder automatic iron remover

Permanent magnet rotating dry powder automatic iron remover

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

Pipe type permanent magnet iron removal series

Pipe type permanent magnet iron removal series

Oil - cooled electromagnetic slurry automatic magnetic separ

Oil - cooled electromagnetic slurry automatic magnetic separ

Water - cooled electromagnetic slurry automatic magnetic sep

Water - cooled electromagnetic slurry automatic magnetic sep

Electromagnetic slurry magnetic separator series

Electromagnetic slurry magnetic separator series

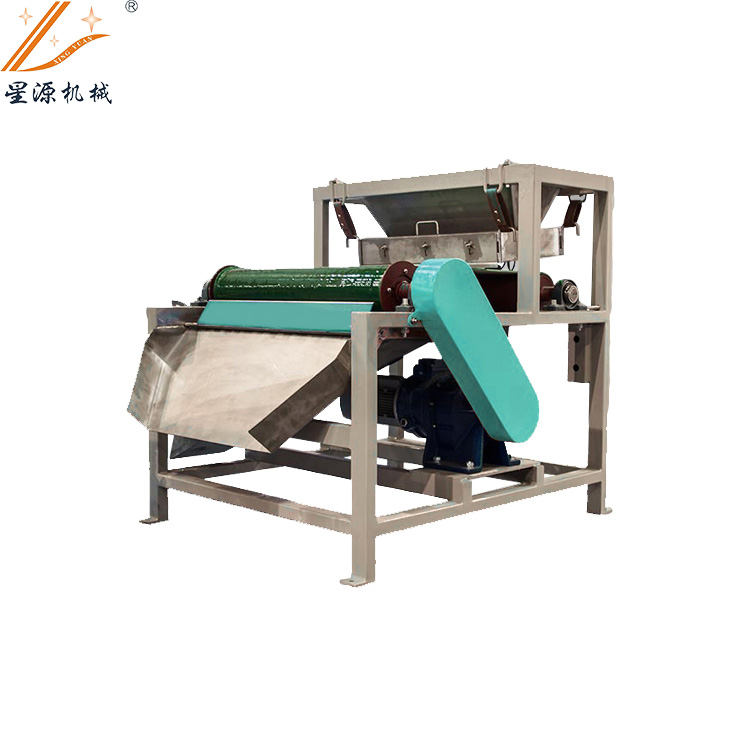

Dry permanent magnet roller belt type iron remover series

Dry permanent magnet roller belt type iron remover series

Permanent magnet drum type magnetic separator

Permanent magnet drum type magnetic separator

Electromagnetic dry powder magnetic separator series

Electromagnetic dry powder magnetic separator series

Stainless steel roller screen series

Stainless steel roller screen series

High magnetic water processor

High magnetic water processor

Permanent magnet belt iron remover series

Permanent magnet belt iron remover series

Suspended rare earth permanent magnet iron remover

Suspended rare earth permanent magnet iron remover

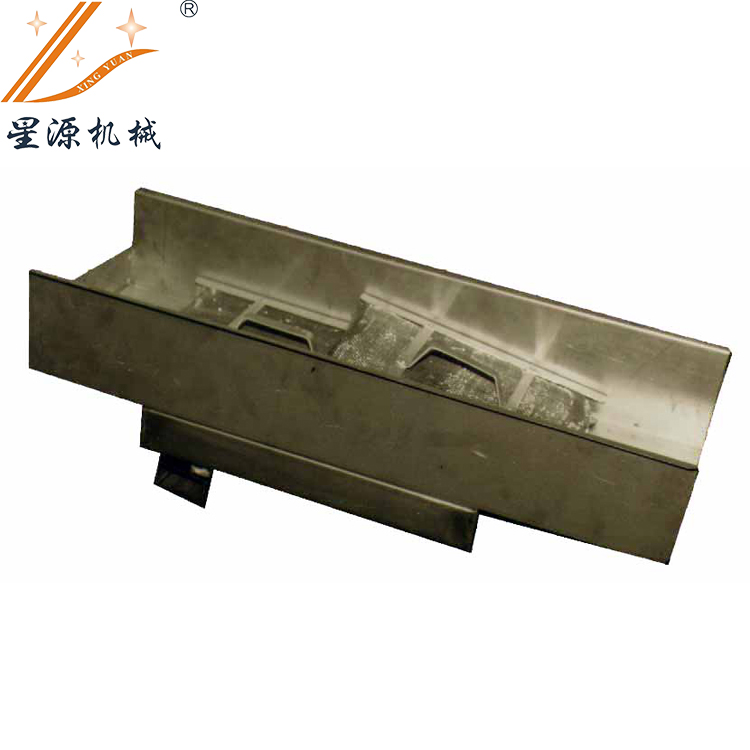

Rare earth permanent magnet chute plate iron remover

Rare earth permanent magnet chute plate iron remover

Rare earth permanent magnet pipe type iron remover

Rare earth permanent magnet pipe type iron remover

Dilute earth permanent magnet grid rotary iron remover

Dilute earth permanent magnet grid rotary iron remover

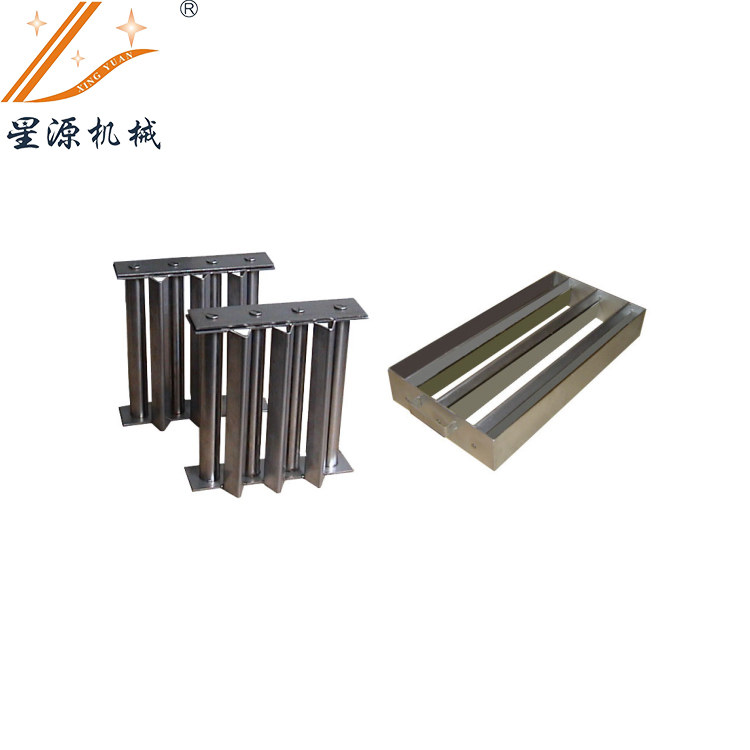

Rare earth permanent magnet grid type iron remover

Rare earth permanent magnet grid type iron remover

Rare earth permanent magnet high gradient magnetic filter

Rare earth permanent magnet high gradient magnetic filter

Drawer type iron remover with rare earth permanent magnetic

Drawer type iron remover with rare earth permanent magnetic

Rare earth permanent magnetic bar and bar type iron remover

Rare earth permanent magnetic bar and bar type iron remover